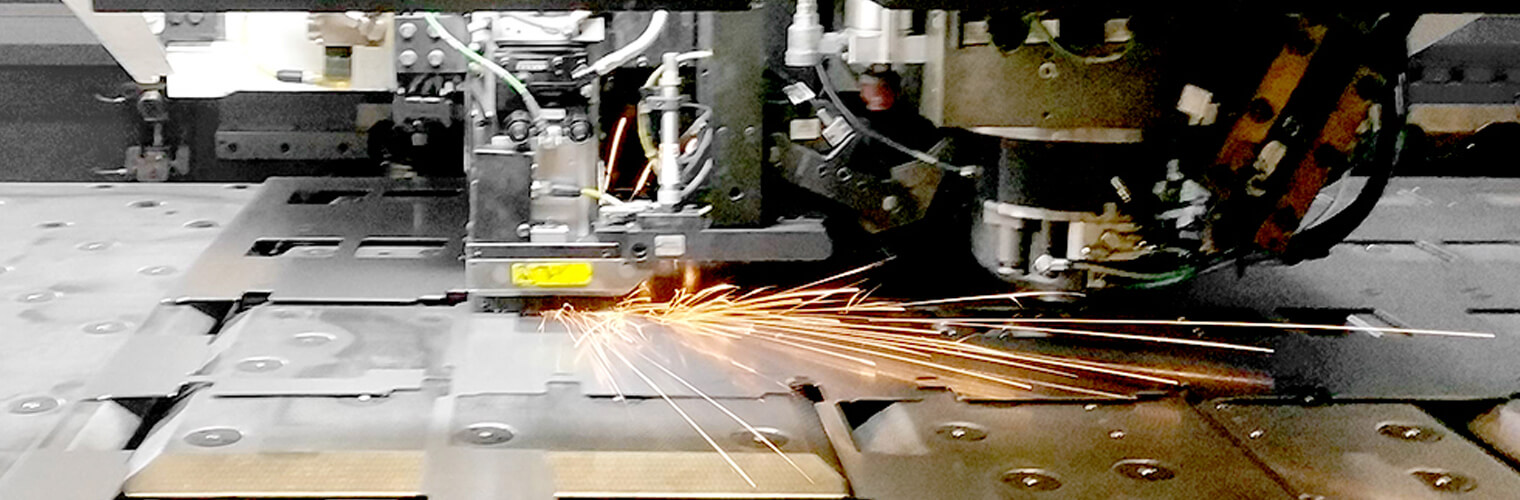

Laser cutting of metal parts is an advanced cutting technique that uses a laser beam to cut and shape sheet metal parts. This technique has become an essential tool in modern industry due to its precision, versatility and efficiency. Next, we will delve into what laser cutting is, how it works, its uses and its history.

What is laser cutting of metal parts?

Laser cutting of metal parts is a cutting process in which a laser beam is used to melt and cut sheet metal parts. The laser beam is focused on a specific point on the metal sheet, and its high energy causes the metal to melt. As the beam moves along the piece, it is cut into the desired pattern.

How does laser cutting of metal parts work?

Laser cutting works using a laser beam that is directed at the metal sheet. The laser can be CO2 or fiber optic and is used to heat the surface of the metal and melt it. The power of the laser beam is adjusted according to the thickness of the sheet metal being cut.

The precision of laser cutting is due to the ability of the laser beam to focus its energy on a very small point. Modern lasers can produce a beam of light with a diameter of just a few fractions of a millimeter, allowing for very precise cuts.

To make the cut, the laser beam is directed at the metal sheet in a specific pattern. The cutting pattern can be programmed into a computer and then transferred to the laser for execution. The cutting process can be done manually or automated, depending on the type of part being cut.

What are the uses of sheet metal laser cutting?

Sheet metal laser cutting has a wide variety of uses in the industry.

Some of the most common uses include automotive parts manufacturing, in the electronics industry for cutting sheet metal parts in the manufacturing of electronic devices, such as mobile phones and tablets.

Also in the aerospace or aeronautics industry, construction and more. In fact, we can affirm that anything metallic that exists today has been manufactured with laser cutting technology.

All the products that you can see on this website are made with laser cutting.

History of laser cutting

Laser cutting was developed in the 1960s and was first used in the manufacturing of parts for the aerospace industry. As technology improved, laser cutting became a widely used technique in industry. Today it is used in a multitude of applications, from electronics to construction.

In its early days, laser cutting was limited to cutting very thin pieces of metal, but as technology advanced, it became possible to cut thicker pieces with greater precision. Today, laser cutting is one of the most precise and versatile cutting techniques available in the manufacturing of sheet metal parts

At Benseny we have different models of Laser Cutting and combined Laser machines at your service from the TRUMF brand to carry out different types of work, whether prototypes or production series.

Visit our page to see the productive resources we offer.