LASER CUTTING SHEET METAL

Laser cutting of sheet metal in the industrial sector, the most used solution due to its precision and speed.

In the industrial sector, laser cutting of sheet metal is one of the most important phases where its high precision guarantees that subsequent manipulations end successfully.

HOW LASER CUTTING WORKS

The laser cutting technique used to cut and shape parts in a multitude of shapes using a high-power laser. The industrial laser technique works with electrical and gaseous energy.

In the industry there are two types of laser cutting machines, CO2 lasers and solid state lasers.

Solid state laser cutting:

More efficient and faster in thin sheet metal due to the energy absorbed by the material more intensely for its wavelength.

CO2 laser cutting:

Known and proven industrial cutting system, robust and tireless. Furthermore, this type of laser leaves us with cutting edges of exceptional quality without rough edges or burrs, ready for the next process.

ADVANTAGES OF LASER CUT

These are the main characteristics that make industrial laser cutting machines indispensable for cutting sheet metal.

Speed, Precision and Efficiency, it also allows us to work with a very wide range of materials. The most common materials are steel, stainless steel, aluminum, anodized aluminum, chrome, brass, copper and titanium.

If you are curious about how different types of lasers can be generated within the machines, here we leave you a link where you can answer all your questions in reference to the techniques used in the different types of high-power lasers. Learn more about laser cutting technologies.

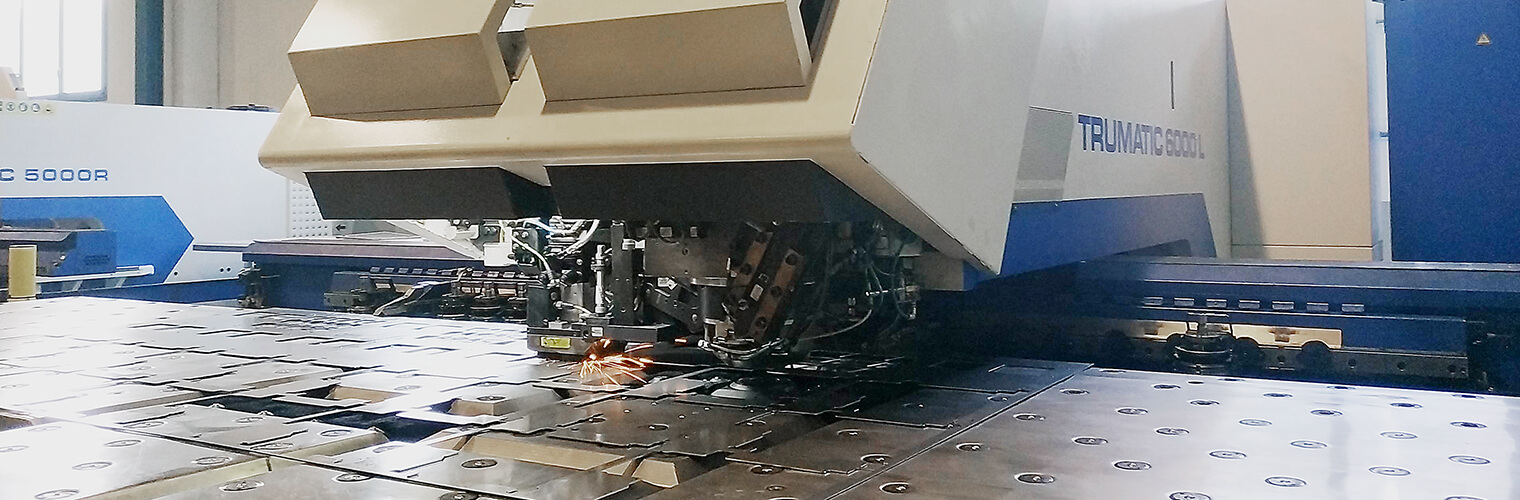

In our facilities we have different models of TRUMF brand laser cutting and combined laser machines at your service to carry out different types of work, whether prototypes or production series.