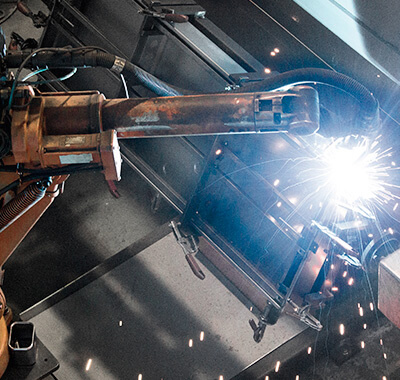

Technique widely used when manufacturing final series, due to the time savings and work precision involved in using industrial welding robots.

Welding with robots reached its peak in the automotive industry in the 1980s. Since then, its use in the industrial environment has grown exponentially.

ADVANTAGES OF ROBOTIZED INDUSTRIAL WELDING

At Benseny we have industrial welding robots to carry out pre-series and manufacturing series of metal products and we can certify that the following advantages are true:

Higher productivity

Best final product

Higher performance

Absolute precision in manufactured products

Less economic impact on the final product

The types of welding that our robots can carry out according to the needs of the product or parts to be manufactured are MIG MAG and TIG (ACC).

Thanks to the advantages of having robotic industrial welding, we can offer continuous quality in the manufactured products and greater speed in their execution.

We can also offer other types of welding, as required for the manufacturing of your metal parts or products.