LIST OF MACHINERY AND BENEFITS

– Space of 6.700m2

– Annual production capacity of around 6000 TN.

– 3D CAD CAD programming (Ansys) finite elements.

– Punching machines combined with high capacity laser.

– CNC folding machines from 1 to 6mts and 8 axes up to 330 TN. Training in norm DIN 6935.

– Hydraulic presses up to 320 TN (1650x1320mm).

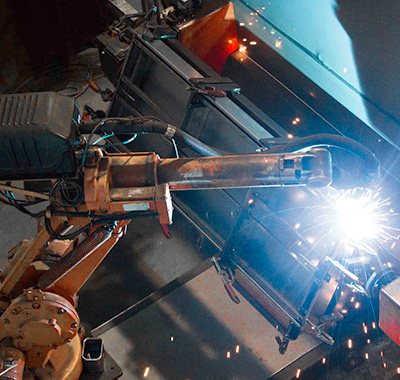

– Robot welding MIG MAG and TIG (ACC).

– High production machining centers with automatic change.

– 6mts shears for thickness up to 10mm.

– CNC tube cutters.

– Automatic truncators.

– Manual welding, prototype, polishing and assembly sections.

– Own transport with vehicles up to 40 TN.

– Ability to load, unload and move pieces of any size to the factory.

– Quality ISO 9001: 2015

– Environment ISO 14001

– Welding ASME 9 and EN 15085-CL3